Shell Size

Drum shells need to act as solid acoustic unities as the foundation to a great drum sound. For SONOR, it starts with the shell diameters, which are optimized to give the drum head the space to float freely, allowing unrestricted contact between the bearing edge and the drum head. This manufacturing process supports precise tuning and best vibration characteristics.

Shell Construction

In 1975, SONOR was the first drum brand to introduce a 45° bearing edge for maximum resonance and sustain. For us, developing the optimal drum is based on our exceptional manufacturing process that has evolved over the years. It's about our unique technique, how we hand-select the wood, and how we specially heat & press each drum shell. Together with many other details and our dedication, this makes the perfect SONOR drum. The result is a tension-free shell with tremendous durability.

The Total Acoustic Resonance (T.A.R.) mounting system

Vibration free mounting results in pure tone and warm sustain. Enhanced by the total acoustic resonance and advanced projection system, the drum enjoys sonic freedom and stays mechanically stable. The patented Acoustigate allows to fine-tune the sonic fingerprint by turning a dial. This results in a beautiful tone and unmatched projection.

The Dual Glide System

The strainer mechanism features a technically perfected snare wire engage-and-release system. Both the strainer and butt sides are equipped with a fast-release snare wire detach function. A fine-tune adjustment knob is employed on both sides. This results in stress free and convenient use at all times.

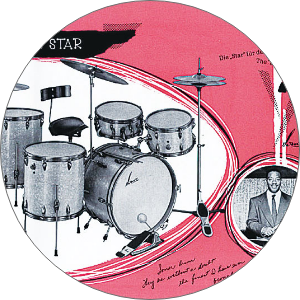

The Passion. The Power. The Performance.

Since its foundation in 1875, the SONOR People has always been a different kind. We strive for innovation and the highest possible quality percussion instruments. Although times, methods, materials and lot of other things may have changed, the goal always stayed the same: Create unique sounding instruments with decades of experience.