100% European Birch

SQ1 drum shells are made of 100% European Birch. Because of its sound characteristics - balanced mids with pronounced lows and highs - the Birch drum sound is very popular for studio recordings as well as live performances. When developing SQ1, SONOR tested several combinations of Birch-based shell materials. SONOR's conclusion was that pure Birch provided the most versatile sounding drum.

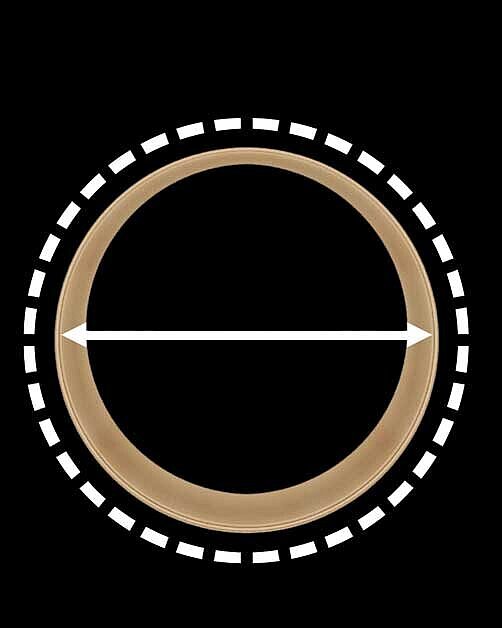

Cross Laminated Tension Free (C.L.T.F.)

Drum shells need to act as solid acoustic unities as the foundation for a great drum sound. We use cross-laminated plies of birch to form a perfectly round shell with great stability. Each ply is laminated at a 90° angle to allow for a shell that is tension-free. SONOR's tension-free shells would keep their round shape even if they were cut in half from the batter to resonant side.

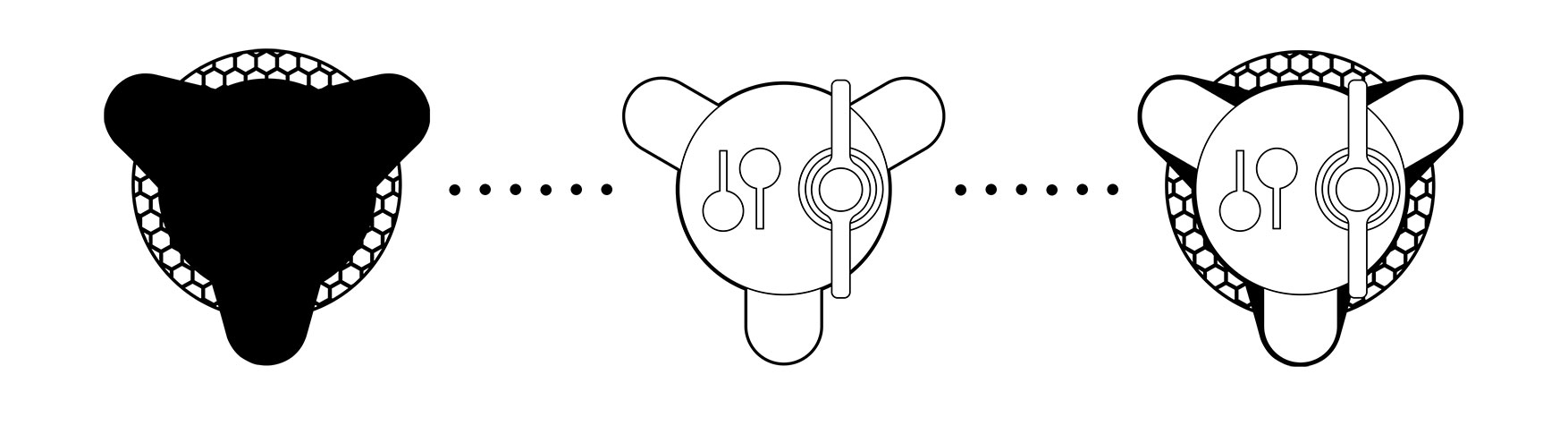

Anatomy of a sound sustainer

Sound Sustainers offer an integrated insulation/mounting solution. Made of heavy duty composite Rubber that originated in the automotive industry, the insulation layer has a unique hexagon structure. It is combined with a metal prism clamp for extra firm grip. Sound Sustainers were prototyped using advanced Selective Laser Sintering (SLS) technology. It is a high end 3D printing process that allows to integrate complex geometries within the construction components straight away. Due to its integrated design, Sound Sustainers need minimal footprint for maximum sound enhancement.

And the sound goes on

The new Sound Sustainer technology enables complete isolation between the metal mount and the wooden shell. This guarantees a particularly long lasting and clean decaying sustain.

As a next step we wanted to find a drum mounting solution that would affect the resonance and sustain of a drum as little as possible while having a small footprint and great stability. Inspiration came from the automotive industry where vibration-control technology is used for engine mounting systems among others. What we developed was a unique concept of mounting toms and floor toms that integrates rubber insulation within the mount to avoid any shell-to-mount contact. Scientific research shows the considerable improvement in extended sustain compared to traditional mounting methods.